Ronny Skauen, CEO of Sleipner Group, joined the firm in 1990 and says he “grew up” in the company. Sleipner, a Norwegian technology and manufacturing company, designs and builds technical marine equipment. It has a keen focus on thruster and stabilisation systems to make boats safer, more comfortable, and more predictable to handle, especially in rough or confined conditions.

Here, Skauen shares how producing critical components in-house has made the company less vulnerable, why integration is a necessary evolution for the industry, and how long-term competitiveness requires real risk-taking.

What were the pivotal moments in your career?

Three come to mind. First, joining the business right after school. Working in both sales and engineering taught me the value of not necessarily knowing every detail, but of understanding the basic physics. That foundation allows you to stay competent across a wide range of technologies.

Second, taking responsibility for our international expansion. That forced me to think globally but act locally: building strong partnerships with distributors who share our mindset and moral values, while also staying directly involved with the main shipyards. Establishing subsidiaries in key markets like Sweden, England, and Italy became crucial.

And third, deciding that we would, in our hearts and minds, be first and foremost a technology company, not just a manufacturer, even though we now produce more parts in-house than ever, and far more than most similar companies.

It taught me that long-term competitiveness requires real risk-taking — and that the courage to invest through downcycles is what separates those who lead from those who follow.

The move toward heavy R&D investment, and later developing advanced electric motors with integrated inverters ourselves, changed everything.

What’s driving Sleipner at the moment?

Right now, we’re focused on making boats behave better at sea, improving the owner’s experience and the vessel’s overall value.

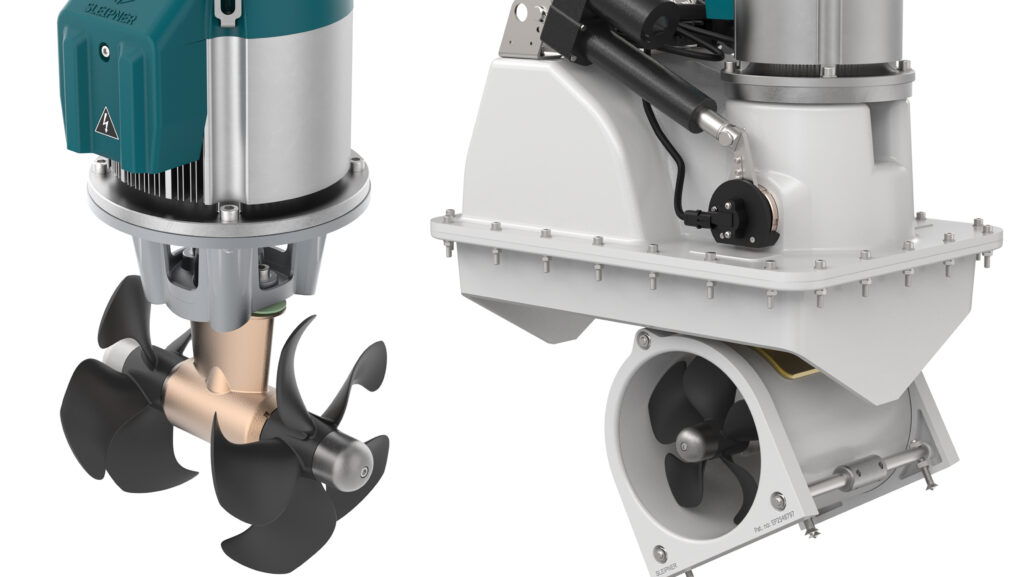

That means pushing thruster and stabiliser technology to become smarter, more energy-efficient, and more compact without compromising reliability. We’ve spent several years developing the next generation of stabiliser fins that deliver much greater performance per space and greater power consumption than anything else on the market. They provide a new level of comfort without the high cost or space demands that come from combining systems with oversized gyro stabilisers.

These fins also don’t reduce speed or fuel efficiency, which makes them a product that truly ‘ticks all the boxes’.

The work isn’t about adding features. It’s about physics, hydrodynamics, and smarter control. Boat owners notice it immediately — less roll, lower noise, better efficiency. The boat feels safer and more comfortable, and that makes boating more enjoyable for everyone.

How does Sleipner fit into the current environmental climate?

Costs are rising, regulations are tightening, and there’s growing pressure to reduce emissions and increase efficiency. We’ve responded by doubling down on engineering quality and local control. We produce most of our critical components in-house, making us less vulnerable to supply chain issues.

We design for energy efficiency because it saves owners both cost and weight. For example, using more efficient thrusters or stabilisers often allows a smaller generator to be installed, directly saving space, cost and weight.

We don’t chase every short-term opportunity. We focus on technologies we know and trust and follow our long-term plan.

Our emphasis on practical energy efficiency fits perfectly with today’s technology landscape. We’ve had this direction for years, backed by deep competence in electrification. And, in true Sleipner fashion, we always aim to make improvements that also deliver tangible operational and comfort benefits for the owner – the only upside in paying more for a product with a smaller environmental impact should not be only the ‘feel good for being greener’.

What’s currently exciting in the marine market?

The major shift is the electrification of onboard systems. As boats move toward hybrid or fully electric propulsion, every auxiliary system must become more efficient and smarter, including thrusters, stabilisers, and support systems like hydraulics.

There’s also a move toward open, modular design, where naval architects and engineers expect systems to integrate seamlessly with onboard control software.

This plays directly to our strengths: mechanical precision combined with smart control and integration. It’s an exciting and necessary evolution for the industry.

What’s happening with your workforce?

We’ve grown steadily, and that’s thanks to the people here. We put real effort into internal training, combining knowledge of machining, electronics, software and assembly. We work hard to keep production competence in Norway, which builds pride and quality ownership into the products.

We’ve also added local engineering in key markets like Italy to work directly and closely with the yards. Generally, we see that the level of automation in both production and general office functions means that, in proportion, we have more staff working on development and innovation than ever. This is also challenging, although probably not as bad in a ‘boating country’ like Norway, compared to other countries.

There is a lot of fact in a statement such as: ‘for boaters, by boaters’.

The industry needs more practical technical people, not just theoretical designers, but those who understand how things are made, installed, and maintained in a boat. That’s where real product quality comes from.

What changes would you make to the market if you had a magic wand?

I’d make systems more compatible and less proprietary. Too much time and money is wasted trying to integrate hardware and systems that were either never meant to talk to each other, or, as often, the companies involved prioritise selfish gains by wanting to sell more of the total package themselves.

Everyone — from shipyards to end users — would benefit.

If the marine sector moved toward common standards for integration, innovation would speed up dramatically.

Can you describe a hard decision you’ve had to make?

The hardest ones are usually about focus and priorities. We’ve had to stop some projects that were ‘good enough’ with customers wanting them, to keep developing the ones that could move the whole industry forward. It’s uncomfortable to pause something that’s selling, but spreading yourself thin kills momentum. Concentration and focus win.

Can you describe a mistake you’ve made and how you recovered from it?

We have more than once underestimated how different real-world installations can be. A system that performed perfectly in our test setup, and even in our own test boat, didn’t integrate well in several customer vessels. We learned to test in many configurations, involve customers earlier, and never assume ‘standard conditions’. It slowed us down at first, but it built long-term reliability and trust.

What’s been your proudest moment?

Being recognised as Entrepreneur of the Year in Norway in 2024 by EY, the world’s largest business competition, was a big moment of recognition for years of effort and achievement.

But winning the local Plankebæreren (Plank Bearer) award — essentially ‘person of the year’ in our city — meant even more personally. It was based on broader criteria than just business success, and looking at the list of previous winners was really humbling.

Actually, I try to find something to be proud of every day, whether it’s a colleague’s achievement, getting nice customer feedback on our product’s performance, or especially when seeing proof that our company lives by the high moral standards we talk about.

Not just doing the right thing, but doing it for the right reason.

The slow change in our industry is quite annoying actually.

What drives your decisions in an industry that changes slowly?

But getting older, I am getting better at handling it. The solution is focusing on long-term thinking.

I believe in doing the right engineering work even if it takes years. If you keep improving physics and mechanics, as well as genuinely having a continuous focus on trying to get better in every area of your company’s operations, you’ll always have a future, no matter how the market shifts.

The post Marine spotlight: Ronny Skauen – Sleipner Group’s CEO – on bringing R&D in-house, focusing on technology, and the need for common standards appeared first on Marine Industry News.

Leave a Reply